“All the world’s a stage,

And all engineering techniques are merely players,

They have their exits and their entrances,

Prestressed concrete, like others, plays a part,

It acts being seven ages. At first the infant,

Stressing and compressing in the inventor’s arms,

Then the curious schoolboy, fondly created,

By imaginative engineers for wealthy customers,

Successfully built but costs a lot of dough. Then the lover,

Whose course never runs smooth, embraced by some,

Shunned by others, especially building officials. Now the soldier,

Produced en masse the world over, quick to fight,

Against any material, not only in strength, but in economy as well,

Soon the justice – codes and specifications set up to abide,

Formulas and tables to help you decide. No more fun to the pioneers,

But so prestressed concrete plays its part. The sixth age,

Shifts to refined research and yet bolder designs,

Undreamed of predecessors and men in ivory towers,

Last scene of all, in common use and hence in oblivion,

Ends this eventful history of prestressed concrete,

As one of engineering methods and materials,

Like timber, like steel, like reinforced concrete,

Like everything else..”

This parody was presented by the legendary Chinese-American engineer T.Y. Lin in World Conference in Prestressed Concrete in San Francisco in 1957. Lin dedicated his equally legendary textbook on prestressed concrete ‘to engineers who, rather than blindly following the codes of practice, seek to apply the laws of nature’ [1] Prestressed concrete is a very simple and beautiful method to apply the laws of nature to ‘command’ it.

Obviously, the first thing to know about concrete is that it has negligible resistance to tensile stresses. For this reason, concrete is ‘reinforced’ for tensile stresses by placing construction rebars. These rebars resist tensile stresses that act on concrete fibers by way of bonding between the rebar itself and the concrete fibers around. (Assumption of strain compatibility)

Conventional construction rebars ‘follow’ the action the concrete fibers take. In other words, they are passive in the sense that they counter stresses that act on the structural member. For example, when gravitational forces act on a simple horizontal beam, internal stresses delevop in beam sections/fibers. Only when these stresses develop the rebars ‘act’ to counter them.

The beauty of prestressed concrete in my opinion is that not only it provides more efficient and economical design in most cases, but it also gives the designer more initiative to implement his/her skills.

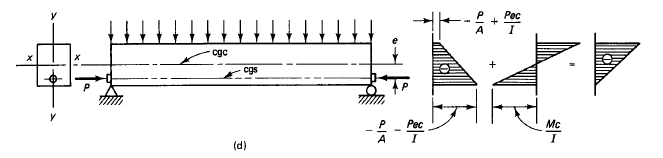

To illustrate this more clearly, let’s start with a brief description of what prestressed concrete actually is. Prestressed concrete is actually imposing internal stresses in concrete fibers by way of high-strength prestressing tendons/strands. This is done by jacking the strands to the determined forces from their end(s). This jacking obviously applies tension forces to the strands. When the strands are released, they try to shorten but the bonding between strands and concrete (or anchorage system in case of unbonded system) prevents this, thus subjecting concrete fibers to compression, which in turn ‘balance’ the tensile stresses in concrete. (Figure 1) [2]

Figure 1 – Stresses acting on a pre-stressed beam [2]

The strands that are used in prestressed concrete technology are by definition high-strength material. They do not have a very clear yield plateau, but in ultimate conditions they can be worked all the way up to 90% of their rupture strength, which is 1860 MPa for most commonly used type. Comparing with conventional construction rebars, this implies they are (0.9*1860MPa/420MPa=) 4 times ‘stronger’ than their counterparts.

Prestressed concrete can be divided to two different methods, depending on time of strand jacking:

- Pre-tensioned concrete: The method in which strands are jacked before concrete is cast

- Post-tensioned concrete: The method in which strands are jacked after concrete is cast

Pre-tensioned concrete is almost always limited to precast concrete technology, in which the strands work to counteract the internal stresses of individual precast members. Pre-tensioning is not only used to strengthen the member, but it also is extremely effective in controlling long-term deflections of members.

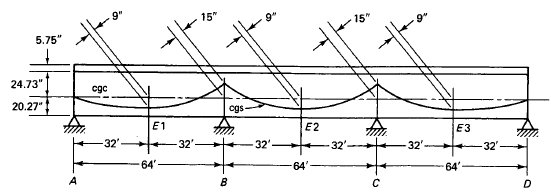

Post-tensioned concrete, however, allows the designer to even more creatively ‘play’ with the structure. Post-tensioning strands can be placed in any desired profile in a continuous manner, hence ‘following’ the moment diagram of the structure, and balancing the loads acting on them by nature. An example of a continuous beam is shown in Figure 2. It can be easily observed that the profile of strands is reflecting the moment diagram of the beam.

Figure 2 – A continuous post-tensioned beam [2]

Prestressed concrete can be used to span considerably long spans with large gravitational loadings. In this aspect they are mostly unrivalled. It also allows the designer to use concrete members with smaller dimensions, thus providing economy and architectural freedom.

Prestressed concrete has very important superiorities to its rivals and can be used in a large range of places including but not limited to:

- Residential buildings

- Parking structures

- Bridges

- Storage structures

- Grandstands and stadiums

- Seismic retrofitting

- Rock and soil anchors

- Slabs-on-ground

Post-tensioning is indeed a ‘live load’, not imposed on the structure by nature, but by the engineer itself. It is not constant and it needs to be studied very carefully. It changes in short-term and long-term, due to numerous phenomena like elastic shortening of concrete, anchorage slip, friction, creep, shrinkage etc.. Also the anchorage design is very important (especially in unbonded method) because any anchorage loss may lead to undesirable results. The designer for this reason should be experienced in the technology.

With our staff who has more than 10 years experience in prestressed concrete, we provide consultancy and software services in this technology.

References:

- Design of Prestressed Concrete Structures, T.Y. Lin, Ned H. Burns, John Wiley & Sons

- Prestressed Concrete: A Fundamental Approach, Edward G. Nawy