In earthquake design of structures, seismic events are defined by their probability to occur within a certain period. According to Turkish Seismic Code, there are 4 earthquake levels:

Level 1 : Ground motions for which spectral amplitudes are expected to be exceeded with a probability of 2% in 50 years (Rate of return: 2475 years)

Level 2 : Ground motions for which spectral amplitudes are expected to be exceeded with a probability of 10% in 50 years (Rate of return: 475 years)

Level 3 : Ground motions for which spectral amplitudes are expected to be exceeded with a probability of 50% in 50 years (Rate of return: 72 years)

Level 4 : Ground motions for which spectral amplitudes are expected to be exceeded with a probability of 68% in 50 years (Rate of return: 43 years)

The term ‘spectral amplitude’ defines the earthquake demand imposed on the building. Obviously, Level 1 defines the ‘strongest’ ground motion and Level 4 defines the ‘weakest’ ground motion. Theoretically, it is possible to design each and every structure to resist Level 1 earthquakes without having any significant structural damage.

However, if we consider the fact that such an earthquake is expected to occur once in 2475 years and a modern structure is not likely to exist in more than 100-150 years, it is not economically viable to do such a design. For that reason, structures are designed according to target Performance Levels, which are defined by the level of structural damage occuring in the structure. In other words, structural damage is permitted to occur in the structure subjected to a seismic event.

To explain more clearly, let’s consider a precast industrial building. If the building does not contain any hazardous exploitable material or if the owner does not demand otherwise, Turkish Seismic Code specifies this building to be designed to satisfy Controlled Damage Performance Level in Level 2 earthquake. The condition of the post-earthquake structure that satisfies Controlled Damage Performance Level can be described as follows:

“Overall damage is moderate. Some residual strength and stiffness left in all stories. Gravity-load-bearing elements function. No out-of-plane failure of walls or tipping of parapets. Some permanent drift. Damage to partitions. Building may be beyond economic repair. Falling hazards mitigated but many architectural, mechanical and electrical systems are damaged.”

FEMA-356, Table C1-2

It is clear that this performance level is mainly focused on providing life safety for building occupants, but building may be beyond economic repair. This solution, based on providing life safety but allowing structural damage, is not acceptable when it comes to industrial buildings with very expensive machinery and equipment.

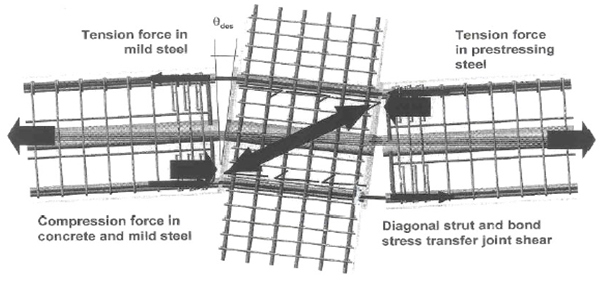

Modern structural engineering is tending towards what is called Damage Controlled Design, in which not only life safety of occupants is ensured, but also structural damage is very limited that the building is fully operational after a seismic event. Precast concrete seismic systems connected with post-tensioning tendons are proven to be one of the most effective materials/systems for this aim. (Figure 1)

Figure 1 – Precast post-tensioned connection (Reference 1)

In precast post-tensioned seismic systems, precast members are connected at site by unbonded or bonded post tensioning strands that are placed through ducts in the beams. The significance of post-tensioning strands is that they are designed to remain elastic and thus providing self-centering capability to the structure and dramatically reducing residual drifts.

The connection behaviour is provided by a ‘gap opening’ mechanism, in which the structural damage concentrates in the joint region itself, rather than the structural members, as occurs in conventional concrete construction. An example can be seen in Figure 2, which shows results of experiments done by Wada et al. (Reference 2) As can be seen, there is significant structural damage and residual drift in the conventional joint, whereas there is very limited damage in precast post-tensioned joint.

Figure 2 – a. Conventional joint b. Precast post-tensioned joint

This system, also called PRESSS (Precast Structural Seismic System), is very efficient in design of especially industrial buildings. Most important advantages are:

- Precast concrete technology is unrivalled in terms of construction speed

- Post-tensioning and pre-tensioning enables gravity members to span long distances subjected to large loadings

- The seismic structural system defined earlier not only ensures life safety in a seismic event, but also limits structural damage and hence provides full functioning of the structure with minimum repair costs after an earthquake.

The only drawback these systems have is that since post tensioning strands are designed to remain elastic and plastic hinging which provides hysteretic energy dissipation in conventional buildings do not occur in these structures, they have limited energy dissipation capacity. However, external passive energy dissipation devices are designed and used in these structures. Our team is also developing such a device working with principle of friction mechanism.

At KULTECH, we provide design services for your projects implementing Precast Post-tensioned Seismic Structural Systems.

References:

- The Precast Hybrid Moment Frame Definition, Clark Pacific

- Study on Damage Controlled Precast Prestressed Concrete Structure with P/C Mild-PRESSS Joint – Part 1: Overview, Wada, Sakata, Nakano, Matsuzaki, Tanabe, Machida